Boating Systems Sys2Sail

by:

K2Sail: The keels

Keel to Sail

A wide range of fixed or lifting keels, produced and tested for over 10 years, applicable in the construction of new boats or for refitting.

- Fixed keel in cast iron o high-grade steel

- "All outside" telescopic keels

- Internal telescopic keels

- Retractable keels with carbon structural case

- Collapsing bulb

H2Sail: Automation on board

Hydraulic to Sail

An advanced management system for hydraulic and electric users for all types of boats. Originally intended for the management and control of our lifting keels, it has been successfully redesigned for a 360 degree application, becoming a single optimized, practical, reliable product.

S2Sail: The boat on your palm

Smart to Sail

An additional module that allows you to share the monitoring carried out by the H2Sail data center with smartphones and tablets, wherever you are.

K2Sail: The keels

From traditional fixed keels to retractable keels, the K2Sail range offers the ideal solution for each owner, from those who are looking for uncompromising performance to those who also want the usability of their boat when cruising with friends or family, passing in a few minutes from the race course to the marina.

K2Sail keel are made with the best materials, certified and engineered according to the international standards, in order to guarantee the maximum safety.

Our technicians are able to push the optimization of the aerodynamic profile to the maximum, exploiting the aerospace tools available to them, in constant collaboration with the boat designers to keep the best trim of the boat.

Selection table

Fixed keels in cast iron or high-grade steel

For owners who demand pure performance without compromise, we make fixed keels with high-performance profiles and minimum resistance bulbs.

In fusion of ductile cast iron, with integral bulb or separated, in PbAn.

Or in steel: more advanced. The box-like construction with high-strength steel (Strenx / Weldox) or stainless steel (AISI 316 and 17-4-Ph) allows to lower the centers of gravity and obtain the maximum straightening moment.

As for all our keels range, full availability to collaborate with shipyards and designers to create a keel completely integrated with the sail plan and with the position of the center of gravity in the desired position.

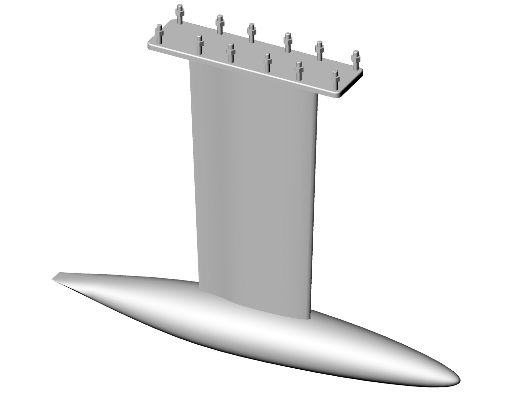

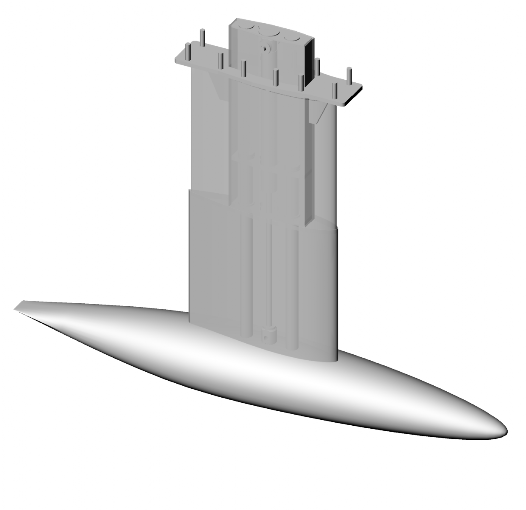

"All outside" telescopic keels

A system that allows the replacement of the old fixed keel with a new one with variable draft without changing the structure of the boat. Widely used in refitting: by copying the impression of the fixing plate, the replacement takes place without upsetting.

In terms of performance, it is generally a less efficient solution than a fixed wing, in relation to which a slight decline in performance can be paid, but in any case superior to a "boot" keel.

By keeping the stresses transmitted to the hull unchanged, the intervention inside the boat is reduced to the installation of the systems only, with obvious advantages also in terms of cost-effectiveness.

By keeping the stresses transmitted to the hull unchanged, the intervention inside the boat is reduced to the installation of the systems only, with obvious advantages also in terms of cost-effectiveness.

The motion is obtained by means of two cylindrical guides embedded in the bulb, constrained to slide inside a steel structure connected to the hull.

The aerodynamic profile is optimized using the same tools developed in the aerospace field, and guarantees the maximum performance of the boat.

The actuation is hydraulic, but can be easily converted into fully electric.

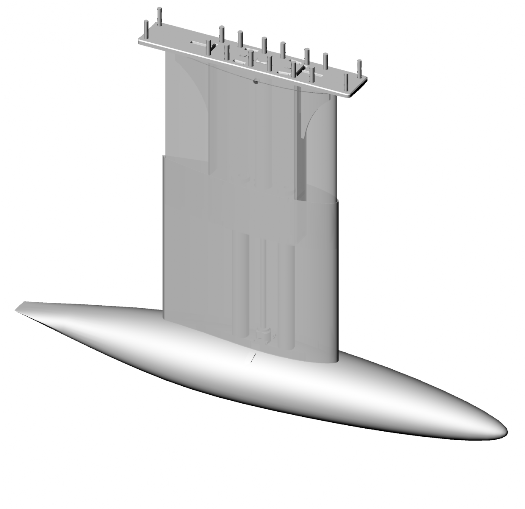

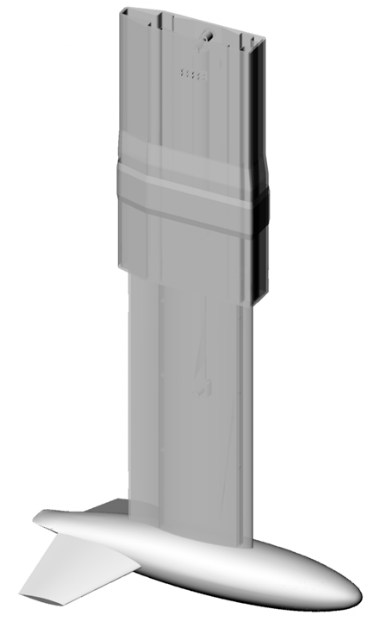

Internal telescopic keels

The internal telescopic keel provides access to the interior of the hull, with an impact that must be assessed on a case-by-case basis, which allows a further step in terms of draft reduction compared to the "all outside".

This configuration, althouh it requires a more invasive intervention, allows quick access to the main components to facilitate inspections and any maintenance.

The motion is obtained by means of two cylindrical guides fixed to the bulb, constrained to slide inside a steel structure connected to the hull.

The actuation is hydraulic, but can be easily converted into fully electric.

The actuation is hydraulic, but can be easily converted into fully electric.

The aerodynamic profile is optimized using the same tools developed in the aerospace field, and guarantees the maximum performance of the boat.

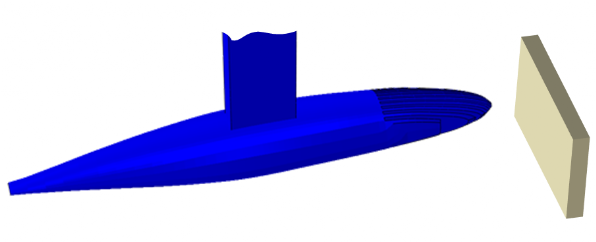

Retractable keels

The retractable keel is the state of the art of this technology. The high efficiency aerodynamic profile of the wing guarantees high performance combined with important draft reductions.

The sliding takes place in special runways placed inside a case made of solid carbon laminate, giving the structure an extreme resistance.

It is the ideal solution for shipowners who demand maximum performance together with the usability of their boat even when cruising with friends or family, passing in a few minutes from the race course to the marina.

The latest evolution of this configuration minimizes structural reinforcements inside the hull, although it is rather invasive due to the presence of the sliding case in the area above the keel itself.

In this configuration the motion is obtained with linear guides obtained in the composite case, while the skids are housed on the wing box. The actuation is hydraulic, but can be converted into fully electric.

The high moment of inertia of the wing box section allows the use of more tapered and performing profiles, with fewer limitations than telescopic keels that have a wider width structure.

The sliding takes place in special runways placed inside a case made of solid carbon laminate, giving the structure an extreme resistance.

It is the ideal solution for shipowners who demand maximum performance together with the usability of their boat even when cruising with friends or family, passing in a few minutes from the race course to the marina.

The latest evolution of this configuration minimizes structural reinforcements inside the hull, although it is rather invasive due to the presence of the sliding case in the area above the keel itself.

In this configuration the motion is obtained with linear guides obtained in the composite case, while the skids are housed on the wing box. The actuation is hydraulic, but can be converted into fully electric.

The high moment of inertia of the wing box section allows the use of more tapered and performing profiles, with fewer limitations than telescopic keels that have a wider width structure.

Collapsing bulb

The collapsible bulb allows the absorption of a percentage of the impact energy it crashes into a fixed obstacle, such as a reef.

This eventuality, called "grounding", is the most severe condition for the keel. The design load varies according to the reference standard and it essentially depends on the size and displacement of the boat.

Regardless of the provisions of the standards, the collapsible bulb is designed to undergo strong deformations, so as to absorb energy during the impact, and consequently increasing the stopping time of the boat to safeguard both the crew and the structure.

In particular, by decreasing the deceleration, the stresses transmitted to the hull are consequently reduced, in analogy to the effect of car bumpers.

Some fins are made on the bulb, with an optimized profile through dedicated numerical simulations, which have no impact in terms of fluid dynamic resistance and aesthetics, as they are grouted during the finishing phase.

References

Length 46’ - Draft: 2.0m – 3.0m Bulb: 3000 kg Year: 2006 - "all outside" telescopic

Length 78’ - Draft: 3.0m – 4.0m Bulb: 12000 kg Year: 2008 - "all outside" telescopic

Length 78’ - Draft: 3.0m – 4.0m Bulb: 12000 kg Year: 2008 - "all outside" telescopic

Length 54’ - Draft: 2.4m – 3.4m Bulb: 4500 kg Year: 2009 - internal telescopic

Length 62’ - Draft:2.4m – 3.6 m Bulb: 5700 kg Year: 2009 - internal telescopic

Length 52’ - Draft: 2.4m – 3.4m Bulb: 4500 kg Year: 2007 - "all outside" telescopic

Length 62’ - Draft:2.4m – 3.6 m Bulb: 5700 kg Year: 2009 - internal telescopic

Length 52’ - Draft: 2.4m – 3.4m Bulb: 4500 kg Year: 2007 - "all outside" telescopic

Length 50’ - Draft: 1.8m – 3.0m Bulb: 4500 kg Year: 2007 - internal telescopic

Length 62’ - Draft: 2.4m – 3.6m Bulb: 7000 kg Year: 2009 - internal telescopic

Length 62’ - Draft: 2.4m – 3.6m Bulb: 7000 kg Year: 2009 - internal telescopic

Length 62’ - Draft: 2.4m – 3.4m Bulb: 4500 kg Year: 2007 - "all outside" telescopic

Length 62’ - Draft: 2.4m – 3.4m Bulb: 4500 kg Year: 2007 - "all outside" telescopic

Length 50’ - Draft: 2.4m – 3.4m Bulb: 4500 kg Year: 2007 - "all outside" telescopic

Length 65’ - Draft: 2.4m – 3.4m Bulb: 4500 kg Year: 2007 - "all outside" telescopic

Length 50’ - Draft: 2.4m – 3.4m Bulb: 4500 kg Year: 2007 - fixed keel

Length 54’ - Draft: 2.4m – 3.4m Bulb: 4500 kg Year: 2007 - fixed keel

&

&

Length 100’ - Draft: 4.2m – 3.2m Bulb: 15000 kg Year: 2017 - retractable with structural case

Length 56' - Draft: 2.3m – 3.2m Bulb: 4700 kg Year: 2019 - "all outside" telescopic

Gallery

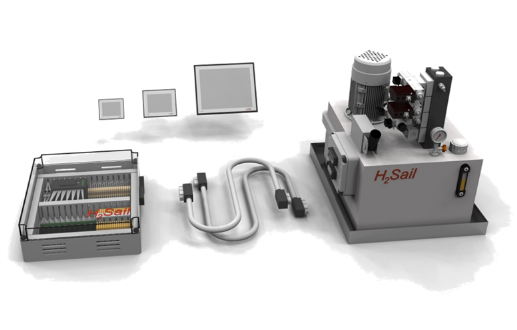

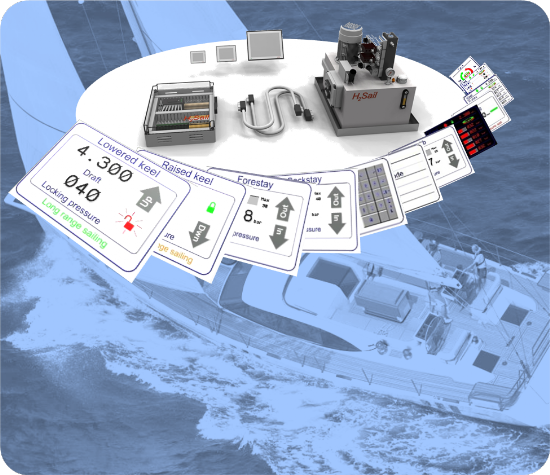

H2Sail: Automation on board

H2Sail (Hydraulic to Sail) is an advanced management system for hydraulic and electric users for all types of boats. Originally intended for the management and control of our lifting keels, it has been successfully redesigned for a 360 degree application, becoming a single optimized, practical, reliable product.

H2Sail integrates traditional control push-button panels with a touchscreen and an immediately readable graphic interface, thus allowing you to monitor or modify all the operating parameters of the on-board equipment.

H2Sail is composed of:

- data processing unit complete with fuse and relay board

- user interface consisting of one or more touchscreen monitors, connected to the control unit via the Ethernet network

- dedicated customizable software

- hydraulic unit with tank, collection tank and fittings entirely made of AISI 316 stainless steel

- manual emergency pump

Each product is prepared, configured and tested before delivery;

Installation takes place on board using the pre-wired multipolar cables (supplied). The input, output and power signals run on separate lines;

The connection of the cables to the data center and to the hydraulic unit is carried out by means of special connectors with restraint system. In case of failure, the data center can be replaced in a few minutes;

In / Out Spare are provided to allow a certain flexibility of system expansion in case of new users connection;

The system is fully expandable thanks to the CanBus fieldbus and the various expansion modules available.

H2Sail can be configured by different levels (from Basic to Customer) which provide for an increasing control of the other onboard users, thus becoming a single monitoring tool for the whole boat.

Configuration level Modulo | Basic | Standard | Advanced | Full | Customized |

management of the only keel by push-botton panel | X | X | X | X | Configuration tailored to the individual need of the designer or owner (*) |

management of the keel by graphical interface | X | X | X | ||

management of hydraulic users for the running rigging | X | X | |||

management of all hydraulic and electrical on-board users | X | ||||

(*) each module can be used individually or in combination, also on motor boats. Optional modules: • backup data center: it is an exact copy of the data center that can be quickly replaced, thanks to the plug'n play connection. It allows functional recovery in case of failure of the control unit initially installed. • safety module: excludes the plc in the event of an emergency (eg impact with lightning) and transfers control of the utilities to an electromechanical system; • additional module for Internet connection: allows diagnostic assistance and support for remote maintenance interventions via the web all over the world. | |||||

S2Sail: The boat on your palm

S2Sail is an additional module that allows you to share the control performed by the H2Sail data center with smartphones and tablets.

In practice, the small pocket device, which follows us everywhere, turns into a very powerful tool that allows you to keep under control every parameter of the on-board equipment, switch on the anchor light remotely, check the internal temperature, check the charge status batteries, select webcams and observe what happens inside or outside the boat and much more.

The communication between smartphone and data center, on board, takes place via Wi-Fi access point.

The communication between smartphone and data center, remotely, takes place via web server.

S2Sail is available on the Android platform. It is currently being developed on the iOS platform.

Frigerio Marco s.a.s., based in Milan, designs and manufactures special equipment, custom accessories and automation systems for pleasure boating.

Seventy years of experience acquired in the field of metal construction and a great passion for the sea.

Seventy years of experience acquired in the field of metal construction and a great passion for the sea.

Since 2007, Rossocarbon s.r.l. offers aerospace, industrial, military and naval engineering services. The skills gained in the calculation and structural optimization, in fluid dynamics, in the definition of composites are translated into the last step of the evolution of the sliding keels, together with the passion for the development of new innovative products.